Industrial waste gas treatment equipment

The peculiar smell of chemical waste gas is very harmful to the human body. It not only causes great pollution to the surrounding environment, but also causes great harm to the health of the employees of the chemical plant and the surrounding residents.

(1) Sulfur-containing compounds, such as hydrogen sulfide, mercaptans, dimethyl sulfide, thioethers and sulfur-containing heterocyclic compounds, etc.;

(2) Nitrogen-containing compounds, such as ammonia, amines, nitriles, nitro compounds and nitrogen-containing heterocyclic compounds, etc.;

(3) Carbon, hydrogen or compounds composed of carbon, hydrogen, and oxygen (lower alcohols, aldehydes, fatty acids, etc.).

Among the eight malodorous substances that have a greater impact on the human body are: hydrogen sulfide, ammonia, trimethylamine, methyl mercaptan, methyl sulfide, carbon disulfide, styrene, and dimethyl disulfide. The foul gas we usually refer to refers to the gas with foul smell diffused in the air.

Third, the characteristics of exhaust gas

2. Most of the emissions are irritating or corrosive.

3. There are many types of floating particles in the exhaust gas, which are harmful.

The floating particles excluded from chemical production include dust, flue gas, acid mist, etc., and there are many kinds of them, which are more harmful to the environment. Especially when the floating particles and harmful gases exist at the same time, it can produce a synergistic effect, and the harm to people is more serious.

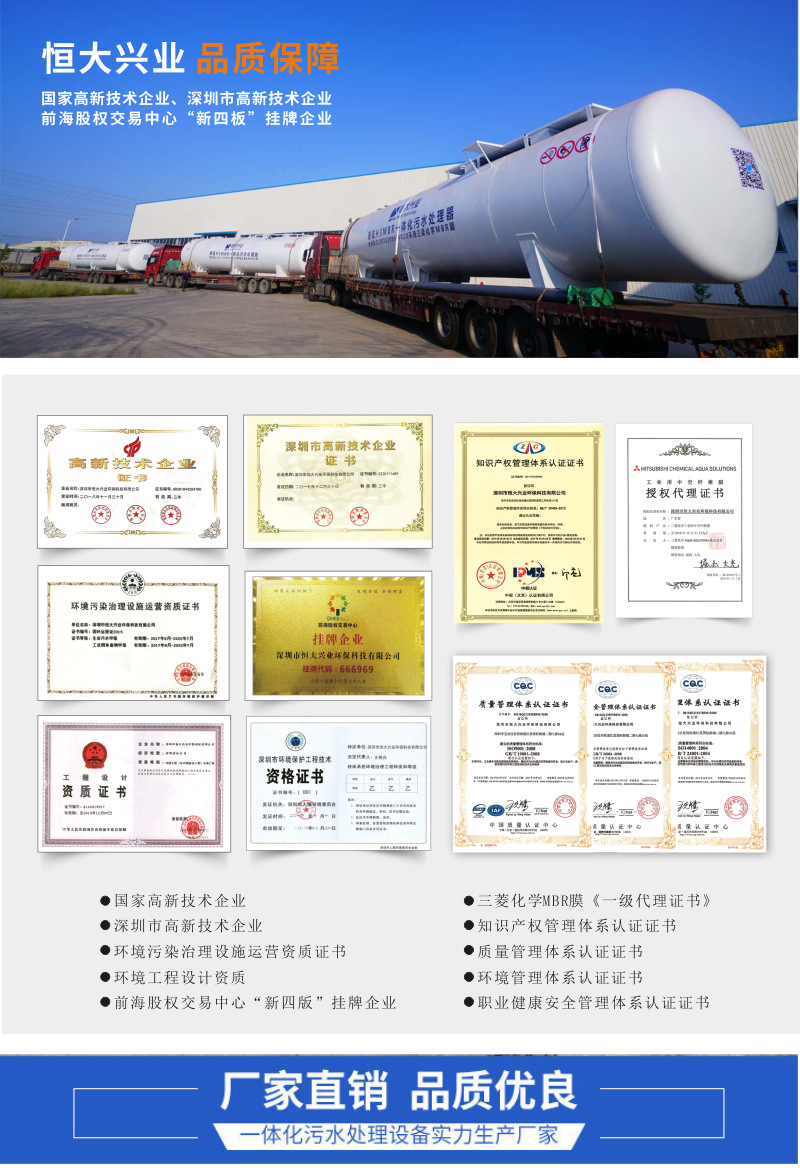

Shenzhen Evergrande Xingye Environmental Protection Technology Co., Ltd. is a kind of waste gas treatment technology applied to the chemical industry, and the main promotion is that the chemical industry waste gas treatment process is RTO

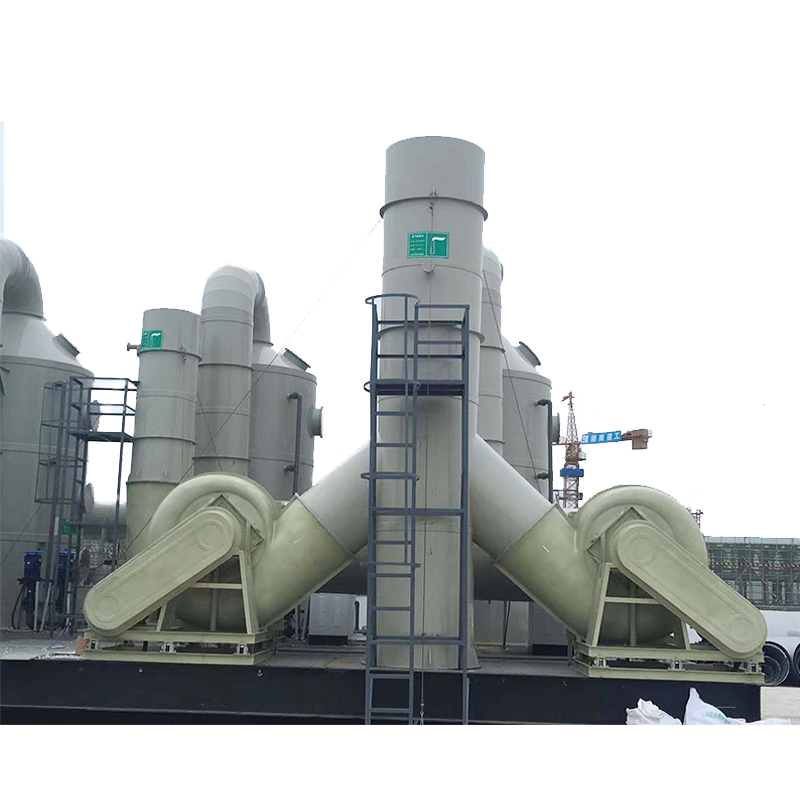

The typical chemical waste gas treatment process adopts the combined process of "multi-stage wet scrubbing + regenerative thermal oxidation (RTO) + multi-stage wet scrubbing" to carry out complete and advanced treatment of chemical waste gas.

The VOCs waste gas from the chemical workshop is first introduced by the front fan to the first two-stage washing tower to remove inorganic waste gas, inorganic salts and a small amount of water-soluble organic waste gas, and then through the demister device to remove the water brought in by the washing tower to avoid equipment corrosion and reduce moisture Entering the RTO vaporization takes away a lot of heat in the furnace.

Advantages of waste gas treatment process

The 10-inch color man-machine interface selected by the touch screen is equipped with corresponding indicator lights and control buttons as an auxiliary. The touch screen displays the process, valve position, fan status, burner status, temperature curve, etc.

2. Visual PLC control interface, manage intelligent all-in-one machine. High purification efficiency, flexible start and stop, low operating cost, convenient installation and use, fast delivery service, space saving, equipment processing efficiency >99%.

3. The exhaust gas real-time IoT intelligent monitoring platform, which provides end customers with equipment operation full life cycle tracking, fast, professional, and reliable operation and after-sales service.

4. There are many engineering cases in the national chemical industry, which can be used as reference for customers;

Last:没有了!

![[nav:name]](/en/static/upload/image/20210731/1627700070576564.jpg)